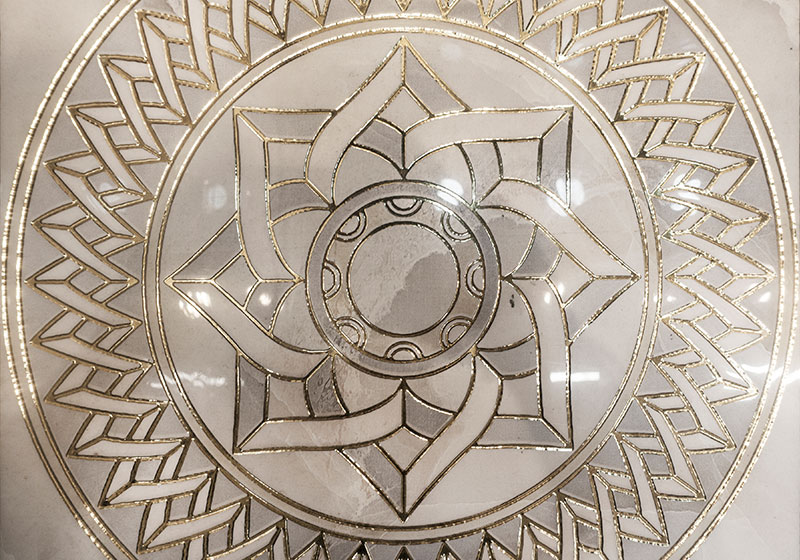

The capabilities of waterjets are endless!

It is the fastest growing precision machine process that is environmentally friendly with great efficiency and productivity. Waterjet cutting technology has taken over due to the fact there no limits to what waterjets can cut. It’s a process that does not require tool sharpening and it cuts with great accuracy leaving clean and smooth edges.

What is Waterjet?

Waterjet technology is basically the flow of water to the pump which then reaches pressures up to 100,000 psi and through high pressure tubing and out to the cutting head.

Waterjets Applications

Advantages

Questions