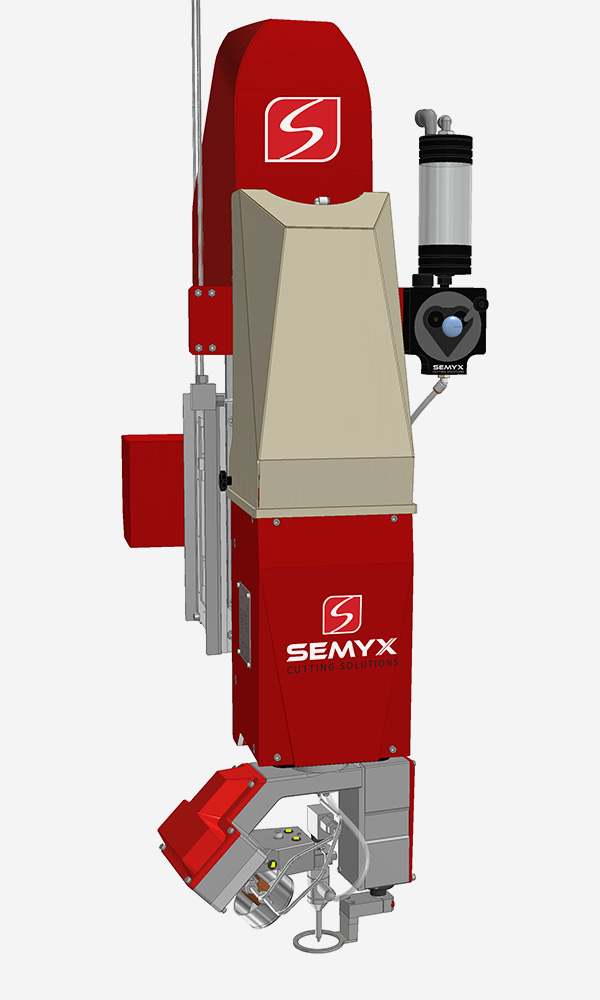

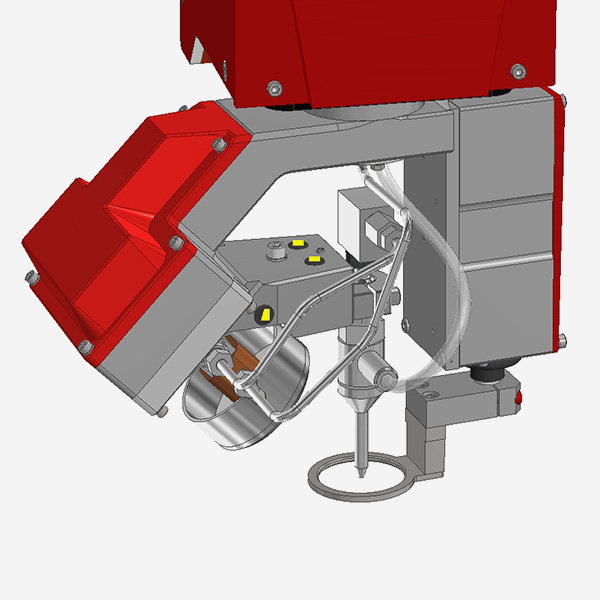

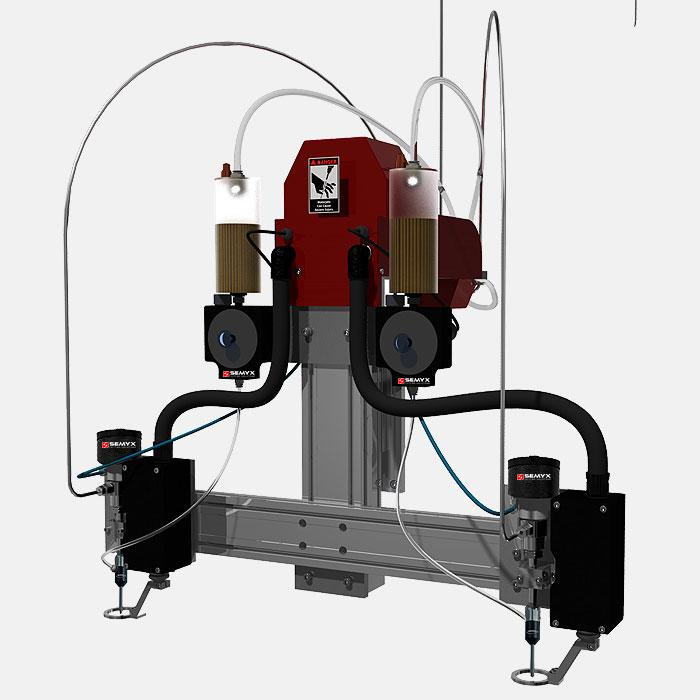

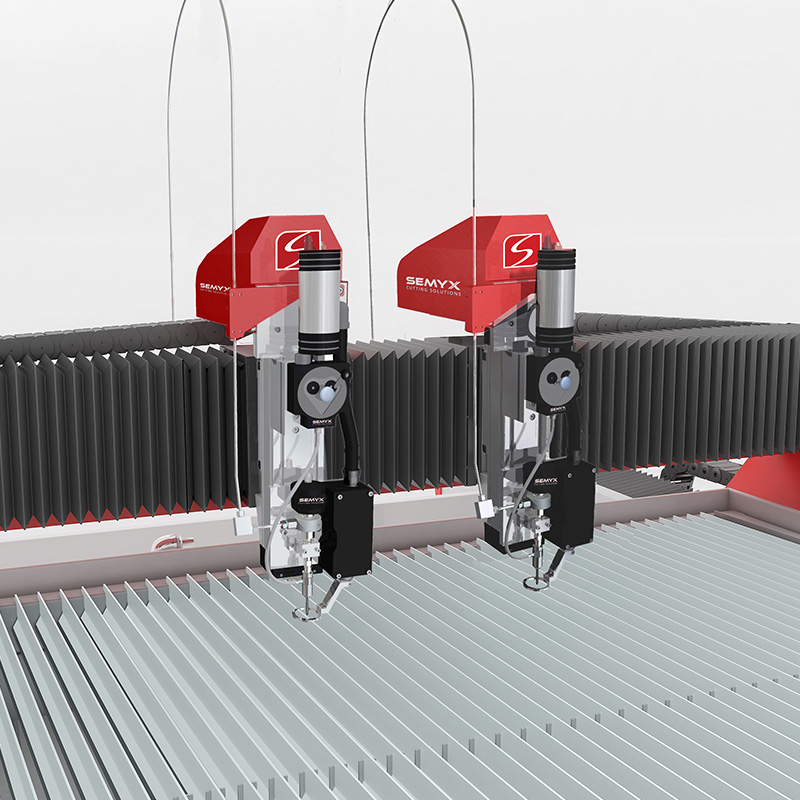

The Semyx Cutting Solution 5-axis head takes the tilting head a step beyond and cuts beveled and 3D parts with a 60 degree angle. Our 5-axis head gives you the ability to cut parts even faster with more accuracy than ever.

- Beveling angle (B Axis): 0° to 60°

- C-Axis rotation Angle: Unlimited (infinite)

- Angular accuracy: ≤ 30 Arcminutes

- C Axis maximum RPM: 17 RPM

- Weight: 40 kg

- Accuracy at the tool center point TCP: ± 0.25 mm

- Abrasive Swivel Joint: Unlimited (infinite)

- Electronic resolution: 0.9′

Addition of the tilting cutting head may reduce the working envelope