- Semyx Cutting Solutions offers various cutting head models for pure and abrasive cutting that can be easily integrated into any waterjet cutting machine.

- The IDE head is a single, easy to use piece.

- The single cutting head piece consists of a body, diamond orifice, and a mixing chamber.

- It has a 90 degree inlet that keeps abrasive from building up at the head.

- It has a flat seal even to the nozzle tube which eliminates risk of breaking the orifice.

- It is very useful for companies with multiple waterjet operators.

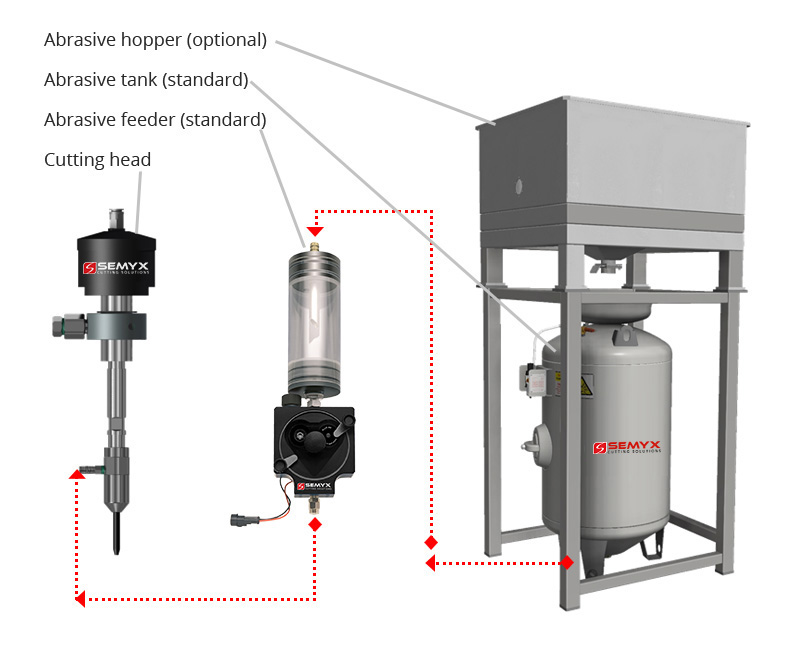

Abrasive Delivery System

Cutting Heads: Abrasive

Cutting Heads: Pure Water

- Pure water jet cutting is used for applications that take in consideration the speed of the waterjet cutting, reliability, and minimal moisture residue.

- The moisture residue is very low because of the very small stream (very small orifice streams) and very high speeds. For that reason alone, pure waterjet cutting is very popular in the paper industry.

- Pure water jet cutting is very commonly used for the following industries, slitting, paper, foam, fabric, insulation, diapers, plastics, leather, and also used in food cutting such as cake and produce.

Abrasive Feeder

- The digitally controlled abrasive feeder, which is controlled by the CNC-controller, ensures the exact supply of abrasive for the cutting process.

- This allows for efficient use of the abrasive material and lowers the cost of consumption of abrasive.

Abrasive Tank

- The Semyx Cutting Solutions abrasive-conveying system with filling-level monitoring ensures that sufficient abrasive is available at all times throughout the cutting operation.

- The uninterrupted supply of abrasive is an essential condition for the successful cutting sequence, particularly in the case of brittle materials such as natural stone, marble, and glass.

Abrasive Hopper

- The Abrasive Hopper is designed for use with 1 ton and 2 tons bulk bags.

- The Performance of Hopper saves valuable time and eliminates manual handling by allowing operators to decant abrasive into the abrasive Tank without any manual lifting.

- Sight glass in front for easy viewing of remaining abrasive.

- Rapid moving valve for expedient filling of abrasive tank.

- A protective cover to prevent the introduction of dust and debris.

Technical Specs

Software

CNC-control with CAM integrated software

This CNC control is especially developed for waterjet cutting. It comes with a fully embedded CAM package.